- Products

- Your Business

- Newsroom

- Tools & Resources

- About us

- CSR

- People & Careers

- Search

- Contact us

- Compare

- Sign in

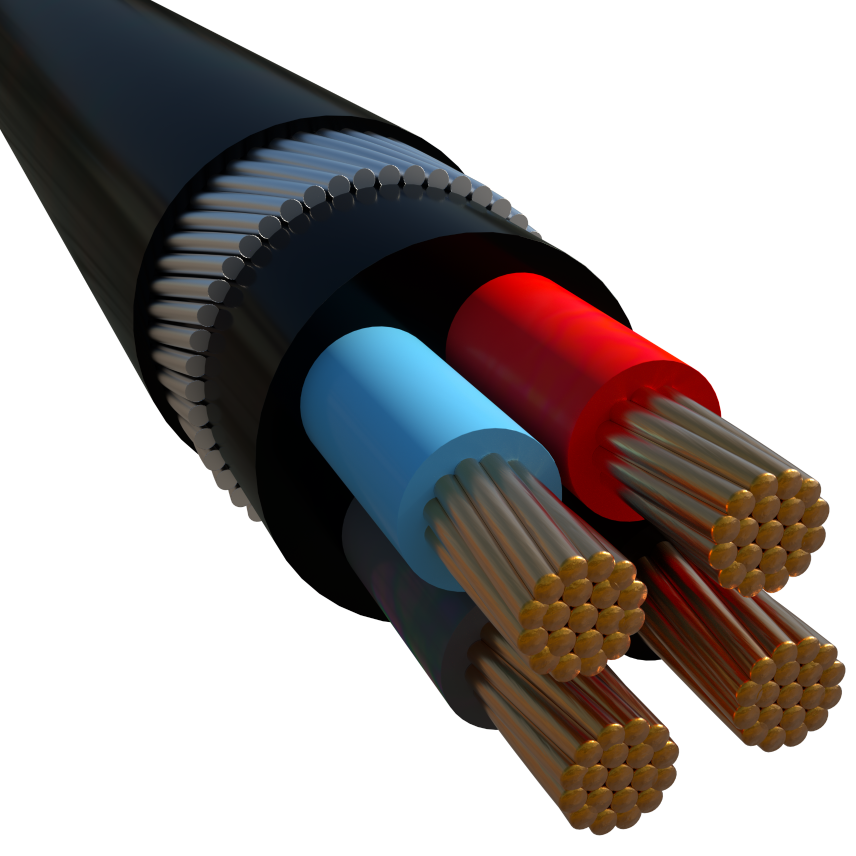

EXR 2*95

EXR 2*95

0.6 / 1 KV POWER CABLES

Conforming to IEC 60502-1

- Nexans ref. : EXR 006210

- Country ref. : EXR 2*95//FR

Description

Description

Standards

-

InternationalIEC 60228; IEC 60332-1-2; IEC 60502-1

1. SCOPE

This specification covers XLPE insulated, circular or shaped, multicore armoured cables, rated at 0.6/1 KV according to IEC 60502-1 for use indoors, outdoors, in cable ducts and for direct burial underground, where severe mechanical stresses are present.

2. CONSTRUCTION

2.1 Conductor

Plain, annealed electrolytic copper conductors, circular stranded, or sectoral stranded, conforming to the applicable requirements of IEC 60228.

2.2 Insulation

XLPE thermosetting material, conforming to the applicable requirements of IEC 60502-1.

2.3 Assembly

Insulated conductors are laid up, filled where necessary with non-hygroscopic material and covered with an extruded thickness of thermoplastic material.

2.4 Armour

Galvanized round wires completely covering the assembly of cores complying to the applicable requirements of IEC 60502-1.

2.5 Sheath

Special Fire retardant PVC based thermoplastic material, conforming to the applicable requirements of IEC 60502-1.

2.6 TESTS

Conforming to the applicable requirements of IEC 60502-1 either on Raw materials or on finished products.

TEST AT WORKS ACCORDING TO IEC 60502-1 & IEC 60332-3

Routine Tests

- Max. DC conductors resistance at 20°C acc. to IEC 60228 & IEC 60502-1 parag. 15.1 & 15.2

- Voltage test acc. to IEC 60502-1 parag.15.1& 15.3

Liban Cables will carry out these tests on all the lengths and tests certificates will be provided.

Sample Tests

- Check of the build - up and color coding of the cable

- Check of dimensions

Insulation : according to IEC 60502-1 Parag. 16.5.2

Armour : according to IEC 60502-1 Parag. 16.7

Oversheath : according to IEC 60502-1 Parag. 16.5.3

Hot Set Test for XLPE insulation: according to IEC 60502-1 Parag. 16.9

These tests will be carried out on one length of each size during each inspection .

Tests certificates will be provided by Liban Cables

Type Tests

Mechanical characteristics on insulation and sheaths material (tensile strength and elongation at break ) in accordance with IEC 60502-1.

Fire retardance test according to IEC 60332-3.

These tests will be carried out on one length of the order.

Tests certificates will be provided by Liban Cables.

Drawing Circular Conductor

Drawing Shaped Conductors

Cable identification - LV cables ≤ 1KV

INSULATION COLORS:

|

|

Neutral |

Cond.1 |

Cond.2 |

Cond.3 |

Cond.4 |

|

1 Conductor |

|

BLACK |

|

|

|

|

2 Conductors |

GREY |

BLACK |

|

|

|

|

3 Conductors |

|

BLACK |

RED |

BLUE |

|

|

4 Conductors |

GREY |

BLACK |

RED |

BLUE |

|

|

5 Conductors |

GREY |

BLACK |

RED |

BLUE |

GREEN |

All numbered control cables (6 conductors and above), are insulated with white color, and numbered with black digits

CABLE MARKING OVER THE OUTER JACKET (by inkjet printing):

LIBAN CABLES DESCRIPTION RATED VOLTAGE SECTION MM2 Year of manufacture meter marking

Other cable identification requirements are available upon request

Characteristics

Characteristics

Construction characteristics

Construction characteristics

Dimensional characteristics

Dimensional characteristics

Electrical characteristics

Electrical characteristics

Mechanical characteristics

Mechanical characteristics

Usage characteristics

Usage characteristics

Resources

Resources

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania